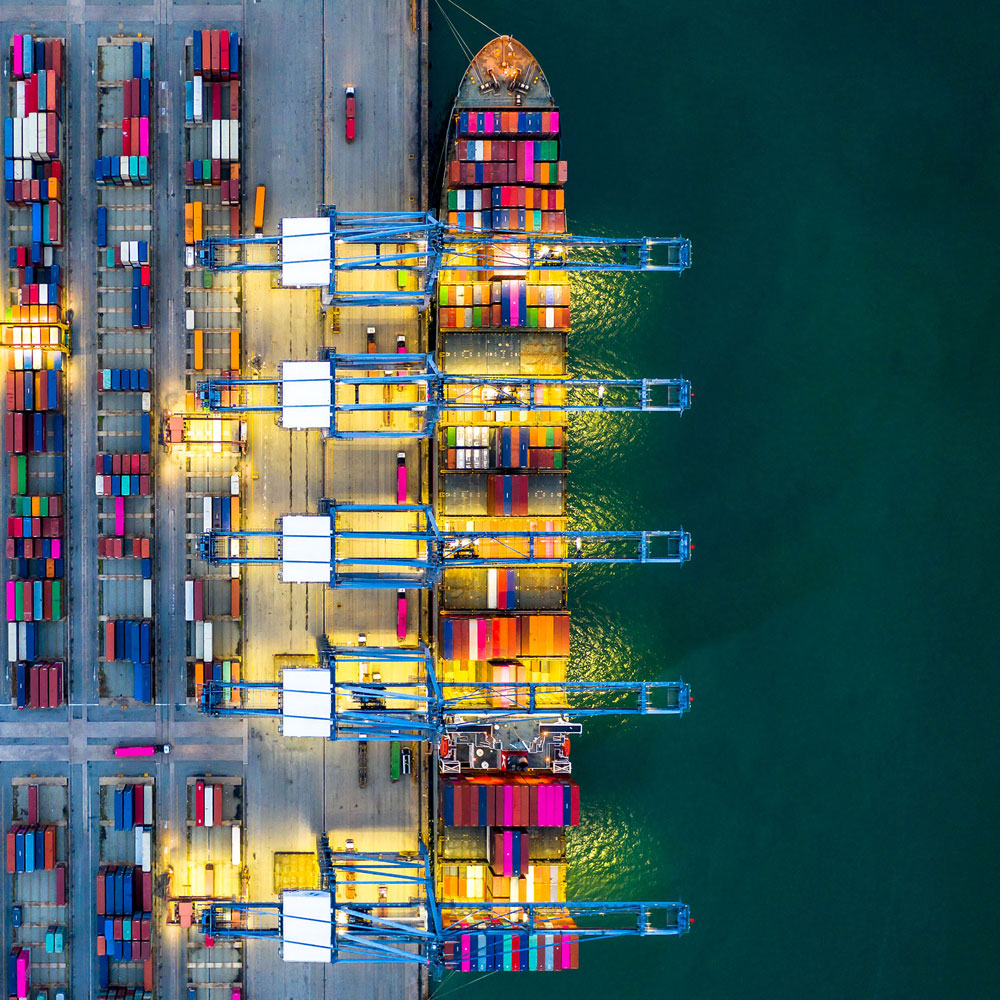

Ports

Power Without Pollution at the Terminal

Mobile, Zero-Emission Charging and Power Solutions for Ports and Drayage Operations

Challenges

The Growing Power Gap in Modern Port Operations

Ports are rapidly electrifying. Yard tractors, terminal equipment, and finished vehicles are all increasing load on already-constrained grid systems. Yet infrastructure expansion remains slow, costly, and complex.

Ports today face:

- Multi-year delays connecting new charging loads due to permitting, construction, and utility constraints.

- Frequent “bricked” EVs arriving on vessels or stuck in carriers, blocking lanes and delaying vessel offloading.

- Vessel-driven demand spikes that fixed infrastructure cannot absorb, producing bottlenecks at key operational windows.

- Limited space for large, stationary charging installations and the inability to place them where they are truly needed.

- Restrictions on diesel generators, limiting use of traditional “wet-hose” charging and temporary power options.

As port electrification accelerates, operators need flexible, scalable, zero-emission power that supports 24/7 cargo movement, not solutions that wait on the grid.

Hydrocharge™

Technical Advantages For Complex Port Operations

HydroCharge™ is a hydrogen-powered, grid-independent DC fast charger and AC genset engineered to operate anywhere across the terminal, providing reliable off-grid power for vehicles, equipment, and remote port zones.

Today’s system delivers 50 kW of continuous power, with future models planned to reach up to 200 kW peak and 100 kW continuous, giving ports a scalable, zero-emission alternative that is often more economical than battery-based mobile charging and competitive with diesel, without the emissions or noise.

Dual Power Modes

- DC fast charging for yard tractors, drayage EVs, and finished vehicles

- AC power (120V / 240V / 400V single and 3-phase) for tools, lighting, maintenance, and temporary shore-power needs

High Power, High Duty Cycle

- Hydrogen provides high energy density, supporting long runtime and high-power operational requirements.

- More economic than battery-based mobile charging, and surprisingly competitive with diesel.

Total Mobility Across the Terminal

- Towable anywhere: container stacks, wharf-adjacent zones, remote berths, overflow lots.

- Eliminates the constraints of grid-tied chargers or immobile generator units.

Continuous 24/7 Operation

- Refuels in minutes—no downtime for battery recharging cycles.

- Supports vessel surges, night operations, and peak auto-processing windows.

Flexible Deployment Models

- Ports with on-site hydrogen: broaden utility of existing H₂ infrastructure; extend clean, off-grid power to more operational zones.

- Ports without hydrogen: delivered hydrogen enables immediate electrification pilots and operational learning without permanent infrastructure.

Beyond Mobile Power

Fuel Cells for Port Vehicles and Equipment

HydroCharge™ plays a critical role in ports by delivering clean, mobile, off-grid power for charging terminal vehicles and supporting operations where grid access is limited or unavailable.

But it’s only part of the story.

Through our fuel cell technology portfolio, we also develop fuel cell engines designed for heavy-duty port and maritime equipment, supporting zero-emission operations for vehicles and machinery that run continuously in demanding environments, from container handlers to reachstackers to terminal tractors and more.

For port operators, this means a broader pathway to decarbonization:

Ports today face:

- Mobile hydrogen power to enable flexible charging and support

- Integrated fuel cell engines to power core, heavy-duty equipment at scale

Together, these solutions help drive our role in advancing clean, reliable power across the full range of port operations.

Case Study

Flexible, Off-Grid Power for High-Volume Port Operations

A major North American port facing accelerating EV imports needs a better way to support yard tractors, finished-vehicle charging, and maintenance power without relying on limited grid access or diesel generators.

EVs arrive at unpredictable states of charge, including frequent “bricked” units in carriers and staging areas. Vessel schedules create sharp, short-window power spikes that fixed chargers cannot handle. Infrastructure upgrades are already running on multi-year timelines.

Deploying HydroCharge units helps:

- Recover bricked EVs instantly and avoid lane blockages

- Provide DC fast charging during vessel discharge surges

- Deliver AC power to remote berths for tools and maintenance

- Support temporary overflow lots (without permitting or infrastructure)

- Reduce dependency on diesel for mobile “wet-hose” charging operations

Results:

- Immediate emissions reduction vs. diesel gensets

- Faster vehicle and equipment turnaround, improving vessel discharge timing

- Operational continuity in areas without grid access

- Lowered operating costs compared to battery-based mobile charging and competitive with diesel

See How HydroCharge Supports Port Electrification

Ports and terminal operators may be eligible for federal and state funding programs aimed at reducing emissions and modernizing energy infrastructure. We help port customers assess incentive availability and integrate the right funding strategies into their deployment plans.

USA | Hyster-Yale Materials Handling, Inc.

129 Concord Road, Building 1

Billerica, MA 01821, U.S.A.

Tel: (617) 245-7500

Fax: (617) 245-7511

EUROPE | European Service and Testing Facilities

Hyster-Yale Italia, S.p.A.

SP ex SS 525 del Brembo, 1

24040 Osio Sopra (BG)

Italy

© 2026 Hyster-Yale Materials Handling, Inc.,

all rights reserved